|

e-mail: amministrazione@allcontrol.it |

|||

|

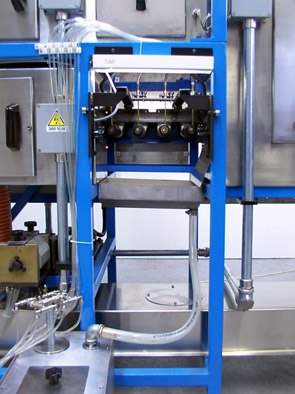

DRIP-FED IMPREGNATION OVEN TYPE FIGG-70 |

|

||

|

|

|

||

|

In the machine we can distinguish: -

the loading/unloading zone -

the impregnating zone -

the oven where we find: the pre-heating zone, the

gelling zone, and the baking zone. This oven is an impregnating machine that uses

infrared radiated heating for greater efficiency. Each zone of the oven is provided with a system for

adjusting the power input independently, and can be programmed for each piece

program. |

|

||

|

|

|

||

|

|

The spindles are closed and re-opened automatically

in the loading/unloading zone so the operator can load and unload the machine

without any difficulty. The pieces pass from the loading/unloading zone to

pre-heating, then to the impregnation zone. They pass through the gelling

zone, then the baking zone, and on to loading/unloading. The pieces are rotated during the pre-heating,

impregnation, gelling and baking phases. The spindles can be provided with a fixed-diameter

or adjustable gripper (in the latter case, from 4mm to 8mm). The index system transfers the pieces to the

drippers in the impregnation zone. From the control panel, it is possible to control

the dose of resin and the dosing speed. |

||

|

|

|

||

|

Up to 99 piece programs can be memorised. |

|

||